Description

Product description:-

This product is highly effective, economical and environmentally friendly fire retardant treatment for fabric of most types. It can be used as a fire retardant and impregnating agent on practically all water absorbent

materials. Solid fire tex can be applied by spraying, padding or immersion, or it can be incorporated directly into a product. The method of application depends on the type of material and structure of the fiber to be protected.

FEATURES

is an aqueous solution of inorganic salts. It is colorless and has a slight odor of ammonia in solution but is odorless when dry.

! is chemically neutral or slightly alkaline with a pH of7.0 to 8.0. Its primary role is to act as a flame retardant.

! does not substantially affect the appearance or feel of the fabric if properly applied. The fabric remains

soft and pliable. Since Solid fire tex is water soluble it can be washed out of both textiles and materials. Retreat after laundering.

! is approved in ready to use, liquid form.

USES

Applications By Industry:

Convention/Hospitality; Furniture; Carpet; Entertainment; Residences; Trade Shows/Exhibitions/Fairs; Senior Citizen Homes; Nursing Homes; Military; Mining; Retail; Pulp and Paper; Libraries; Theaters and Museums; Public Office Buildings; Long Term Care Facilities; Automobile; Recreation Complexes; Publishing; Food Service; Government; Hospitals & Clinics; Hotels & invention Centers; Rodeo (Straw). and other places of public assembly which are required to be furnished with fire resistant materials to protect the public, as well as property, against accidental ignition or arson.

Applications By Product Group:

Textiles: Lab Coats; Coveralls; Velour; Drapery; Curtains; Carpets; Tents*; Work Clothing; Wall Coverings; Cotton and Canvass; Linen (Table Cloths); Upholstery. Paper and Cellulosics: Trade Show

Displays; Straw and Hay; Decorations; Acoustic Tiles; Wood Chips; Sawdust; Packaging; Cardboard; Books and Documents; Crepe Paper; Fiber Roof Board. *The water-soluble properties of Solid fire tex limits these applications. Addition of a sealant is required to protect the Fire Retardant from leaching if exposed to water.

TECHNICAL DATA and PROPERTIES

Appearance/Odor Colorless free flowing liquid/slight

ammonia odor

Specific Gravity 1.04 g/mL

Volatiles/Vol 80%

Solids by Weight 20%

pH 7.0-8.0

Dry Time Dependent upon fabric type and thickness

Boiling Point Not available

Storage Limits Store in a cool dry location away

from direct sunlight. Keep from freezing, above 320 F (00C)

INSTRUCTIONS FOR USE

Typical Application

! Solid fire tex

can be applied by spraying, coating or immersing a fabric at any point in the manufacturing process.

! do not dilute or mix with other products.

! check the fabric for color-fastness before starting the treatment.

! distribute solution evenly across the entire surface, ensuring that solution does not flow or drip to the

extremes whenever possible.

! dry on a horizontal drying rack, at moderate temperature (between 70 and 1750 F) for optimal results.

! tumble dry fabric in a warm dryer, (maximum temperature should not exceed 1750 F).

! iron fabric using a warm iron (maximum temperature2000 F). Iron a small area first, to ensure the color is not affected.

! to spray Solid fire textile Treatment, use a hand held or back pack pressurized spray container with an atomizer nozzle. Filter the solution into the tank to keep out any solids that may plug the nozzle. With daily use, the sprayer must be flushed out with clean warm water.

Coverage rate:

The required quantity depends on the absorbency of the material, its inherent flammability and its overall weight.

As a rough guide:

! the maximum amount of Solid fire textile required is equivalent to the original weight of the material to be treated (80 to 100%).

! i.e.: if the dry fabric starts out weighing 1 lb., then it should pick up between 0.8 to 1 lb. of solution

during treatment and retain an additional net added weight of 5.6 to 7 oz. after drying.

Fabric Cleaning and Care Instructions:

Detergents and water or shampooing (i.e.: of drapes, carpets, etc.) will remove Solid fire tex and re-application will be necessary. Re-treat after laundering

Application to Straw, Paper and Other Cellulosebased Products

Hay or Straw Bales for Display: Approximately 1 quart of Solid fire tex per bale is required for good penetration. Spray on with an atomizer nozzle.

Cardboard: Corrugated cardboard is best treated with a fine atomized spray on both sides. Do not soak material in any one spot for too long a period, since this will warp the cardboard and make it lose its shape.

Paper and Decorative Materials:

Thorough saturation of paper with a spray will work. For best results, hang paper during spraying. Total immersion can be used but a test sample is advised.

Hazard Class

Solid fire tex is not subject to WHMIS Regulations, nor is it regulated by Transportation of Dangerous Goods.

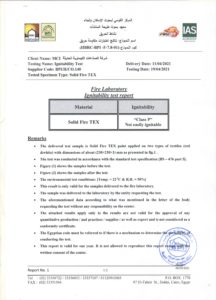

TEST RESULTS

Solid fire tex is tested under CAN/CGSB 4.2 27.1 MS. The results show”a high degree of flame resistance” on fabrics such as:

! Polyester fabrics – 100%

! Cotton – 100%

! Polyester/Cotton blend – 65/35%

Each of these fabrics is a medium weight (drapery/ tablecloth) fabric

CAN/CGSB-4.2 No./N° 27.1-M87

Textile Test Methods Flame Resistance – Vertical Burning Test